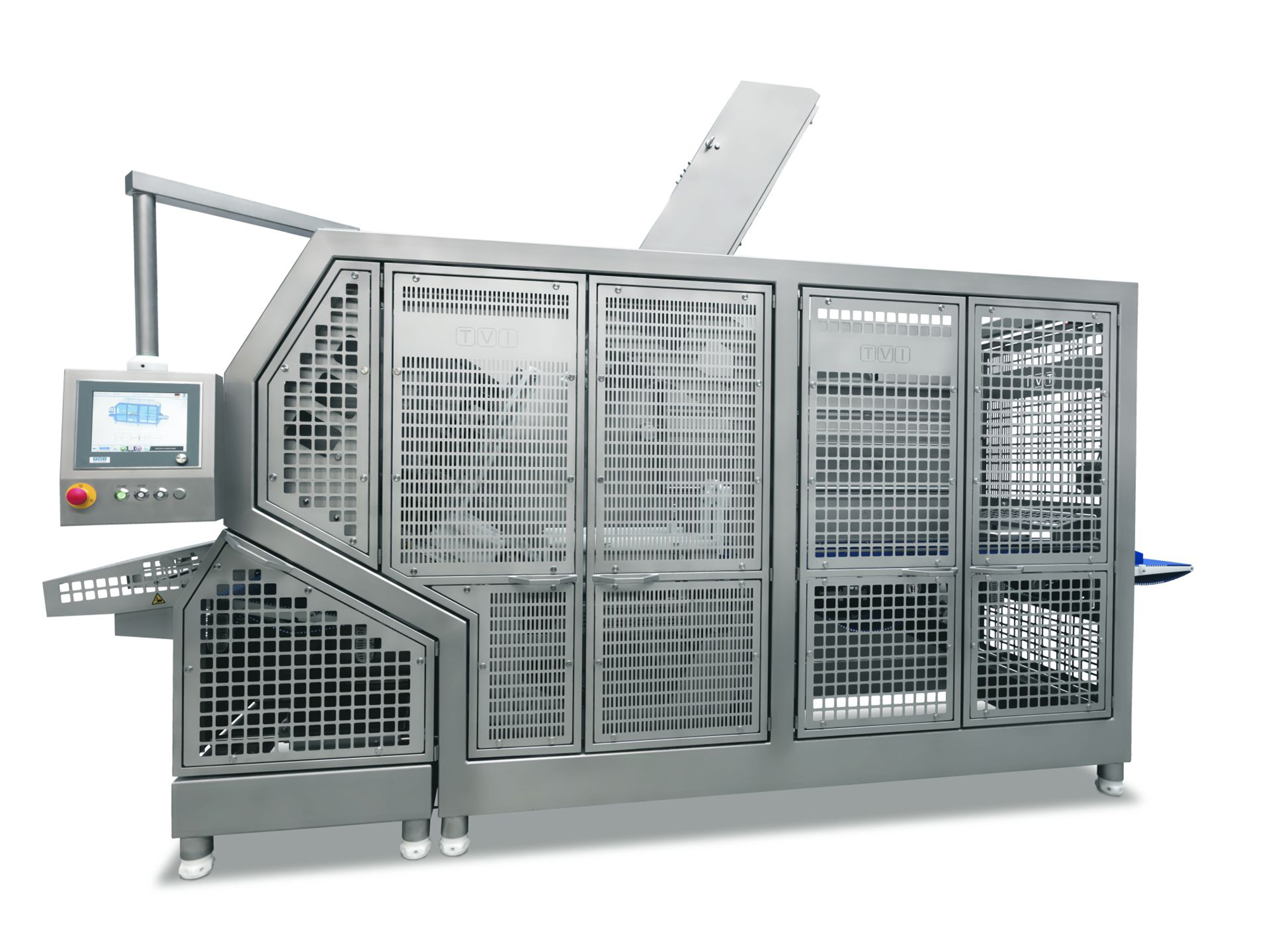

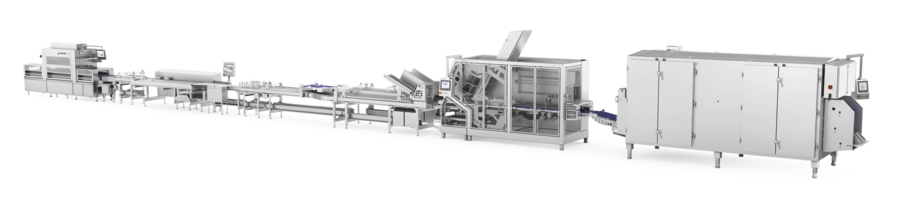

GMS 1600

IMPRESSIVE TECHNOLOGY

- Flexible, three-dimensional forming

- Highest level of cutting quality (with and without bone) due to optimum shear cutting

- Parallel cutting guides and end-stop plate (parallel chops)

- Flexibility (possible applications for the machine): with and without bone, butterfly cut

- Slice thickness from 2 mm

- Different placement variations

- Precise weight portioning, optimised for trim

- Various cutting requirements accommodated (weight, thickness and yield)

- Very simple operation with intuitive menu guidance

- Rapid product change