- Highest level of cutting quality (with and without bone) due to optimum ‘shear cutting‘

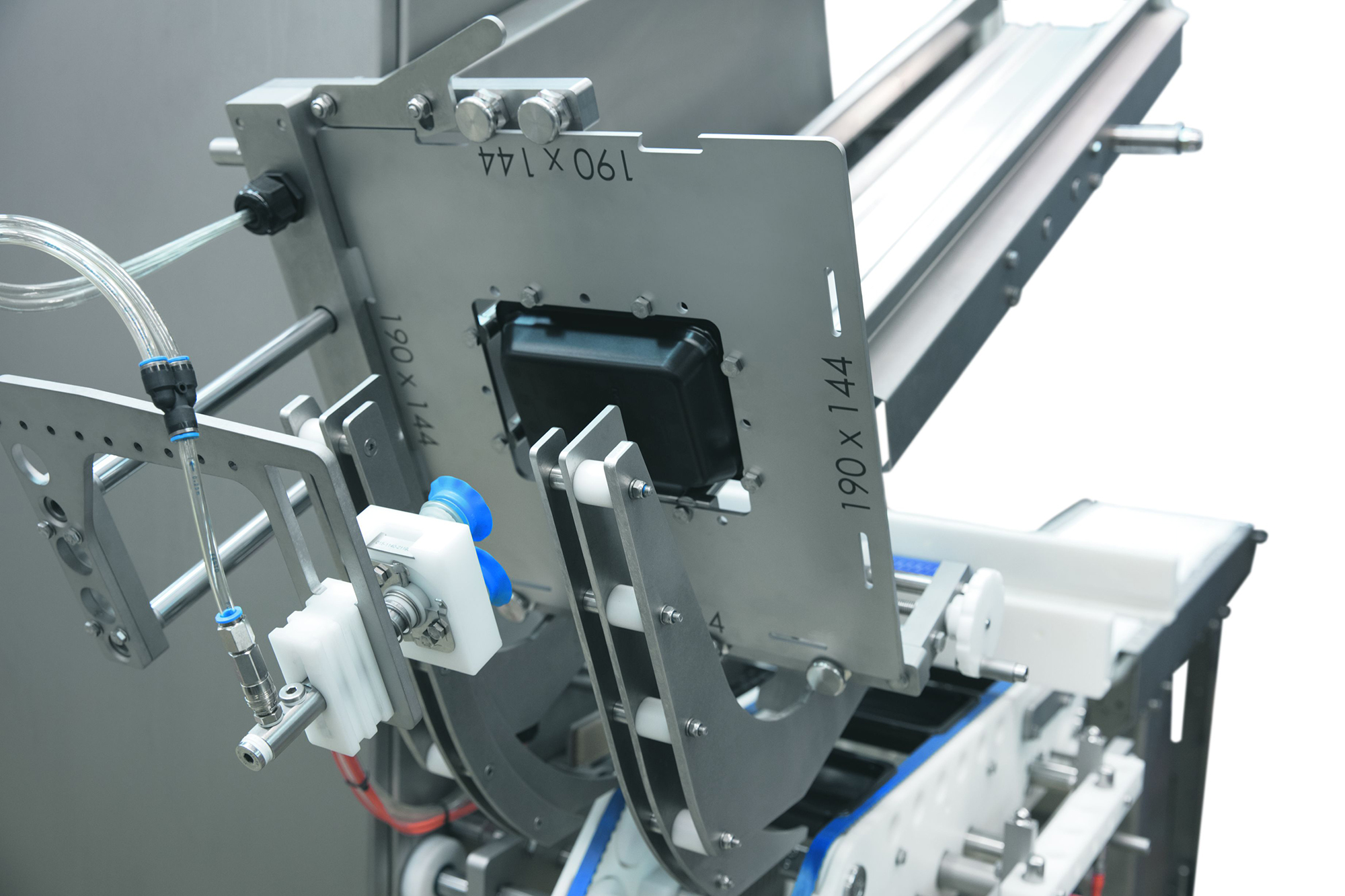

- Parallel cutting guides and end-stop plate (parallel chops)

- Flexibility (possible applications for the machine): with and without bone, diced, strips, butterfly cut

- Slice thickness from 2 to 50 mm

- Different placement variations

- Precise weight portioning, optimised for trim

- Forming and cutting in one process

- High level of visual quality thanks to even forming

- Very simple operation with intuitive menu guidance

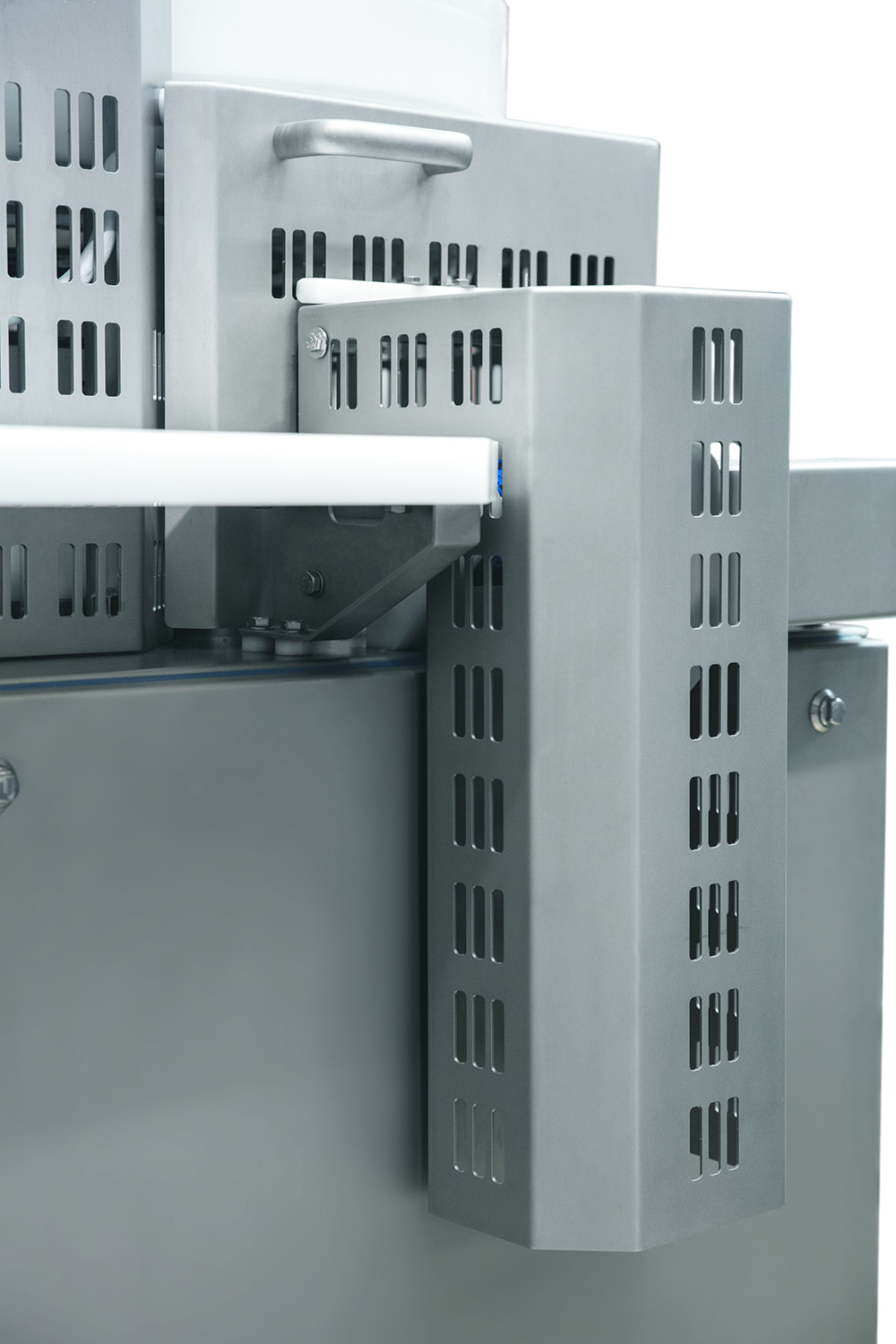

- Rapid product change without tools

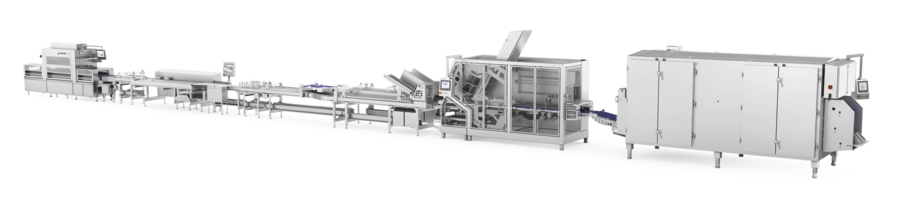

- Line compatibility (line linking with modular TVI solutions)

- Line communication with other TVI equipment (e.g. checkweigher etc.)

MODE OF OPERATION

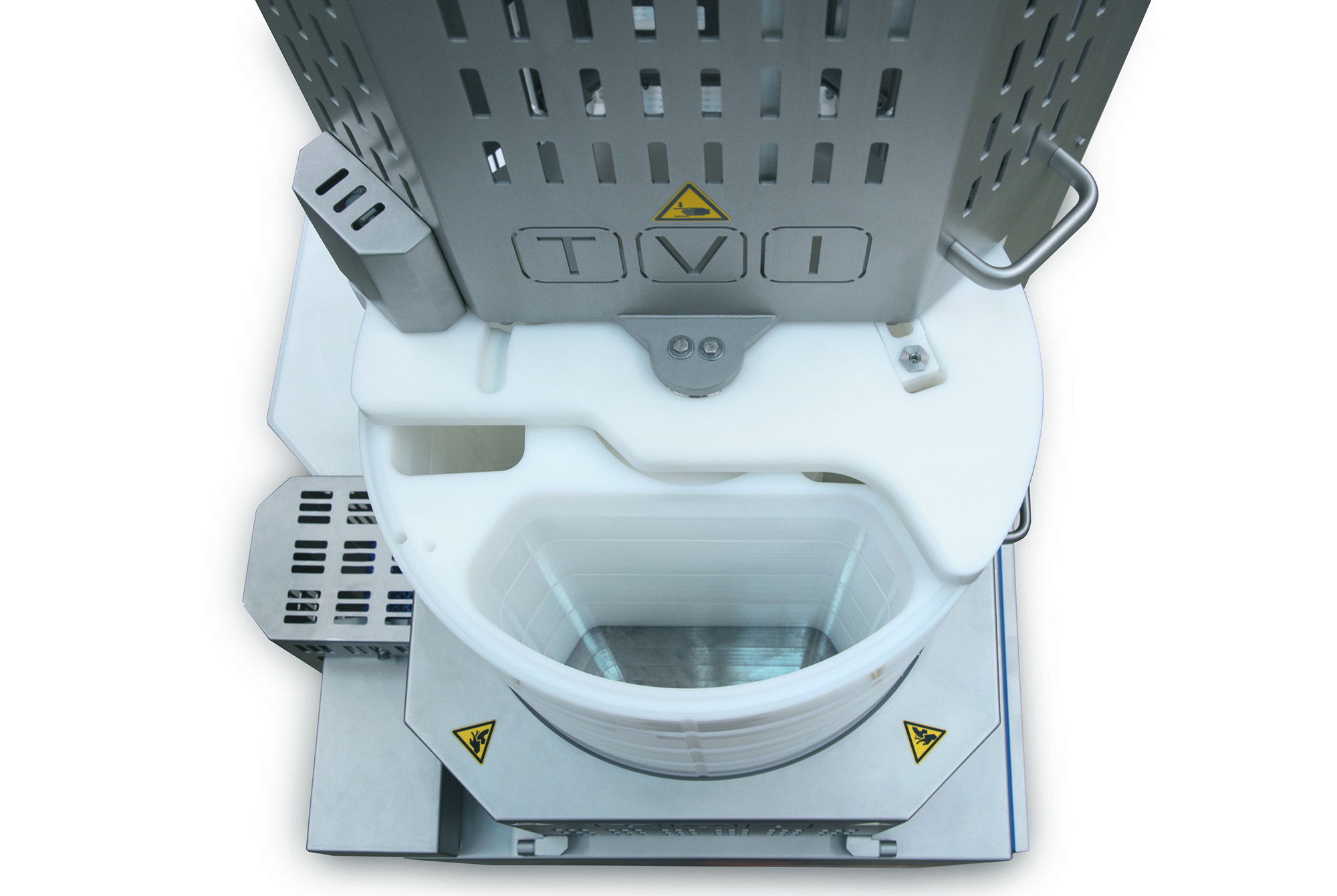

- One or multiple pieces of meat are filled into a cavity of the mold revolver.

- The revolver turns to the portioning position and the appropriate piston drives into the mould cavity.

- The meat is perfectly formed and pressed in a longitudinal direction.

- The GMS can run in waste less mode or if required with a minimum trim.

- Piston and stop plate define the thickness and the fixed weight of all slices individually.

- The GMS cuts continuously without permanent start-stop operations. (just few individual movements)

- Immediately after the last cut the revolver turns to the next piece of meat and the process repeats.

- New features since 2016

- Simple and intuitive operating concept

- New control technology with high-precision timing enabling an increase in performance, more precise placement, smoother running

- Up to 4 cuts per second and short changeover times result in higher performance.

- Different slice weight and placement options possible in the same piece of meat

- Output of the different portions to different downstream processes if required

SAMPLE APPLICATIONS

All types of red meat

- in almost every consistency

- to every portion

- always weight and yield-optimized

- with low labour costs

BENEFITS

- Portioning quality without compromise

- Maximum flexibility (meat with and without bone, diced or in strips)

- Optimum yield thanks to perfect forming

- Highest level of weight accuracy

- A small number of personnel required thanks to automatic single-slice placement or shingling

- Perfect support for downstream processes

go top