ASR 300

IMPRESSIVE TECHNOLOGY

- Consistent quality of skewer appearance, looks hand-made

- Wide range of products, recipes and components is possible (meat, fruit, vegetables, shrimps, meatballs, sausages etc.)

- Flexible skewer lengths and shapes (e.g. round or flag skewers)

- Simplification of the manual processes; this means simple training of new staff

- Very high level of personnel efficiency due to reduction in manual work

- High level of productivity thanks to full automation of part-processes

- Modular integration in TVI line systems is possible

- Fully automatic loading possible with suitable tray sizes

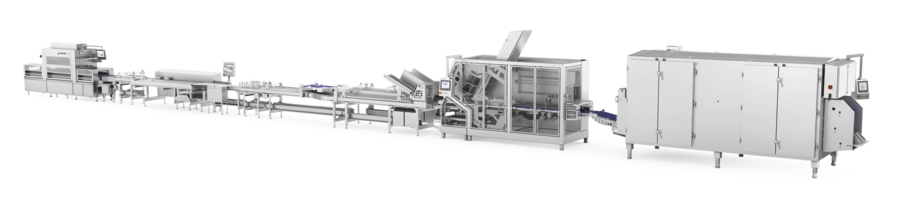

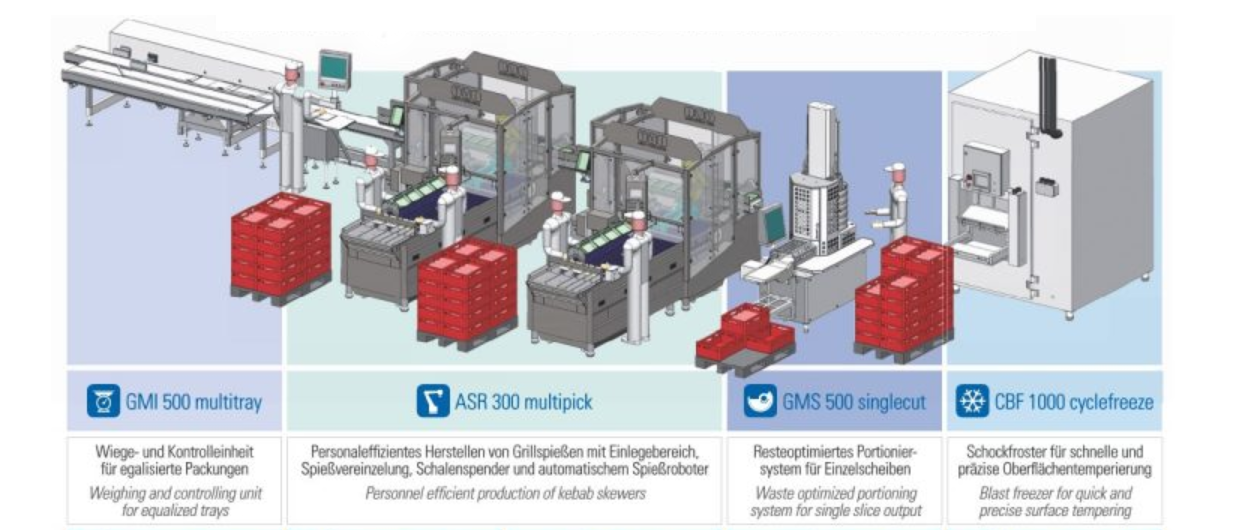

This production line comprises the following TVI modules:

CBF 1000 cyclefreeze

Shock freezer for precise and rapid surface tempering.

GMS 500/520 singlecut

Residue-optimised portioning system for individual slices.

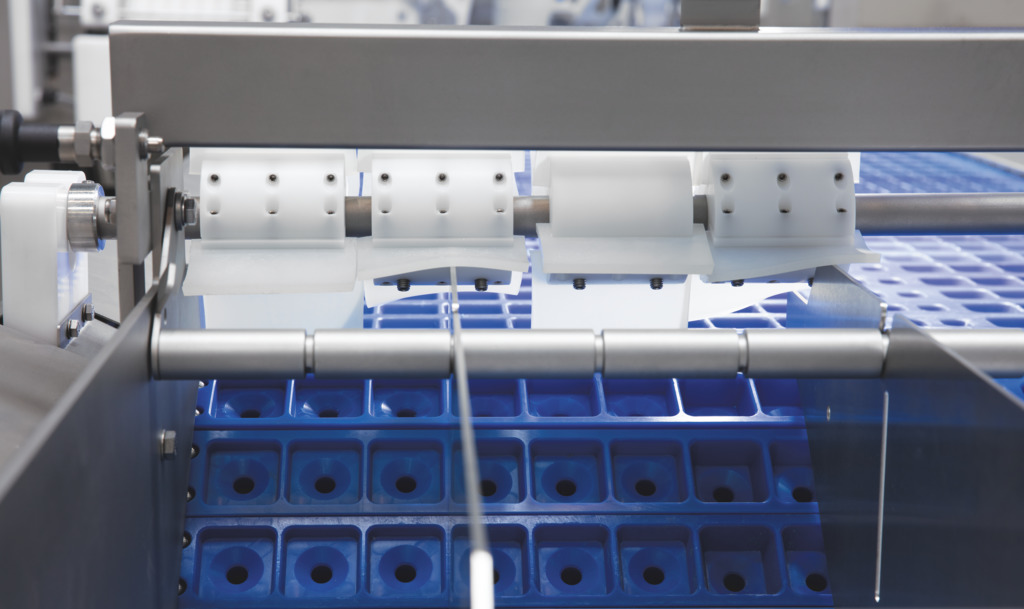

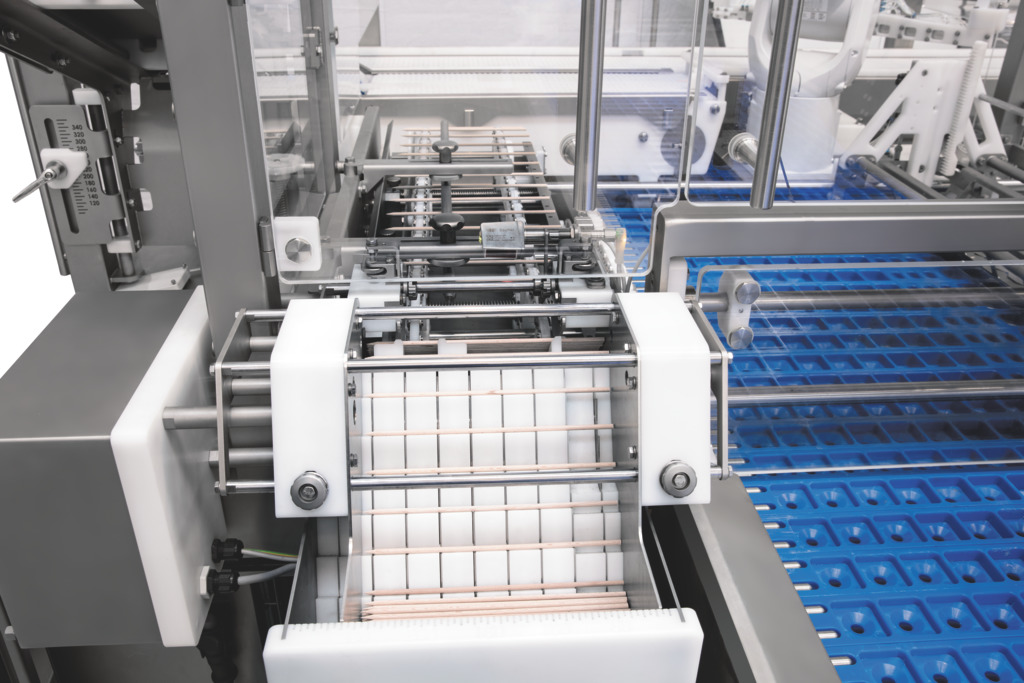

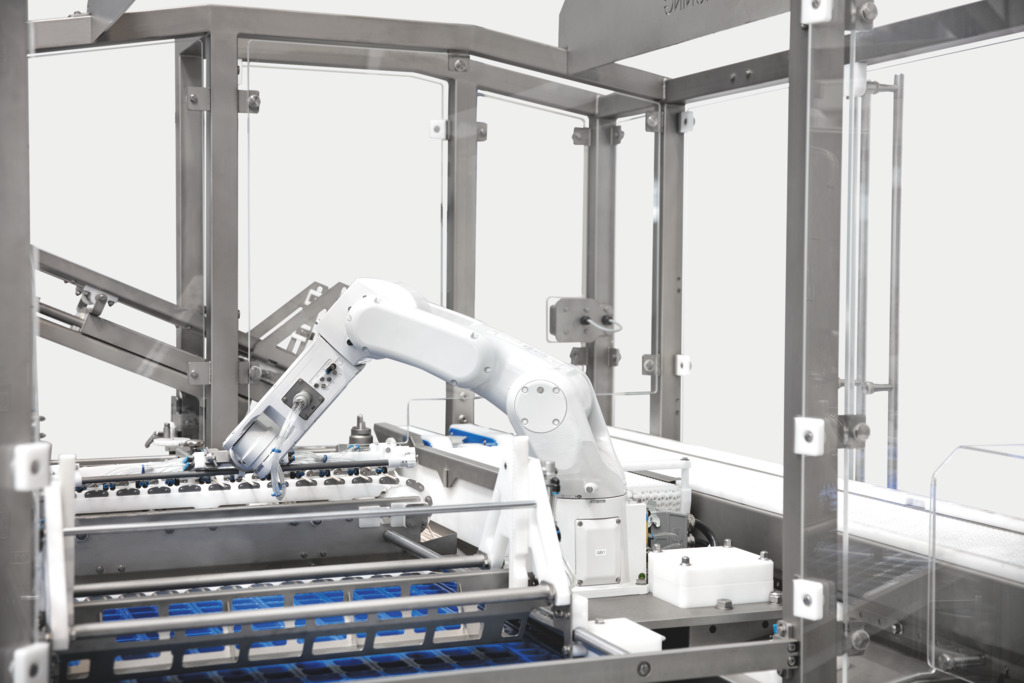

ASR 300 multipick

Personnel-efficient production of barbecue skewers with inlay area,

skewer separator, tray dispenser and automatic skewer robot.

GMI 500 multitray

Weight and inspection unit for equal packs.