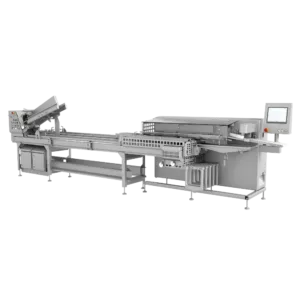

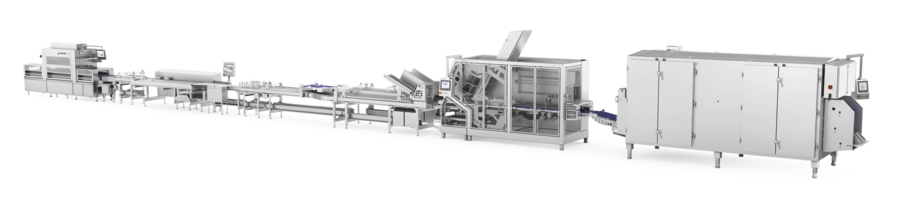

LINE MODULE

The modular line concept consists of perfectly coordinated modules:

- GMS 520 Volumetric portioning system for cutting fixed-weight and yield-optimised portions.

- Waste-free portioning of meat pieces

- Thin quality trim cuts if required

- Shingled portions

- Clean and clear-cutting surface

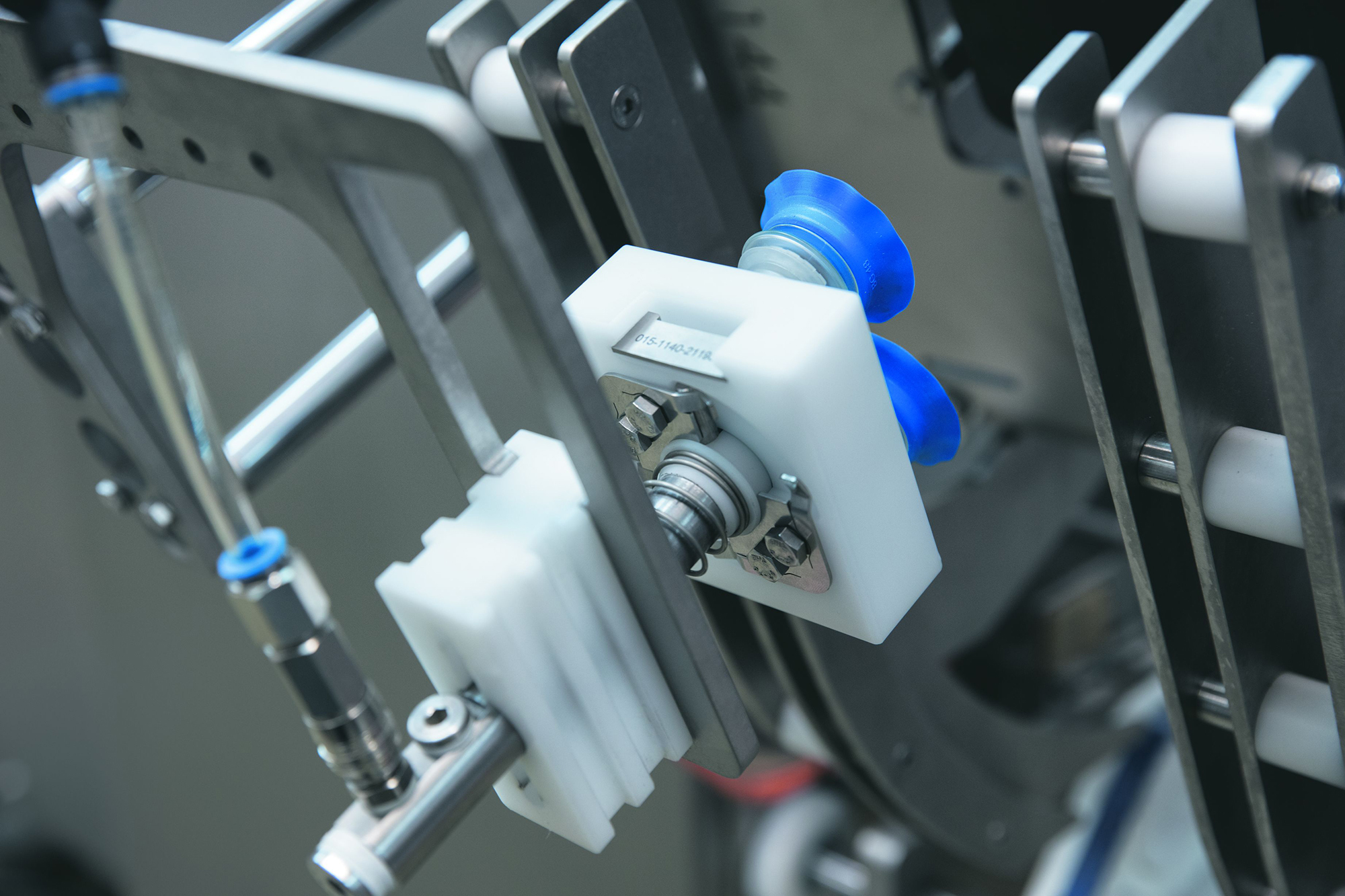

- AIR 520 Auto tray filling using a jump belt

- Integrated TDS 300 tray dispenser

- High reliability

- Precise alignment of a tray

- Multi-layer stacking possible

- GMI 500 Weighing and sorting unit for fixed weight portions consisting of dynamic scale

- Sorting by pushers

- Buffer belts for under- and overweight portions

- Tendency control with feedback for portioning machine