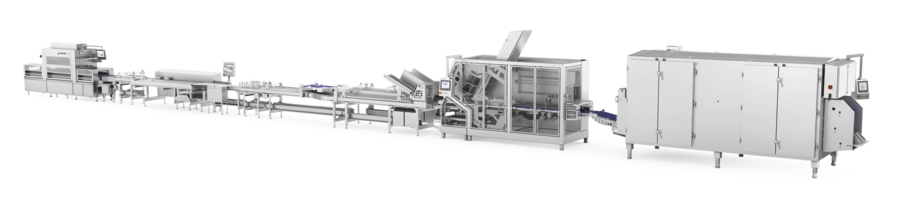

THE FPS 500 CONSISTS OF PERFECTLY MATCHING COMPONENTS:

MIS 3000-4000 multitray

Ergonomically designed, manual inlay area with 3 or 4 meters length consisting of

- Tray dispenser TDS 300

- Meat conveyor

- Tray conveyor

- Optional: Centering unit

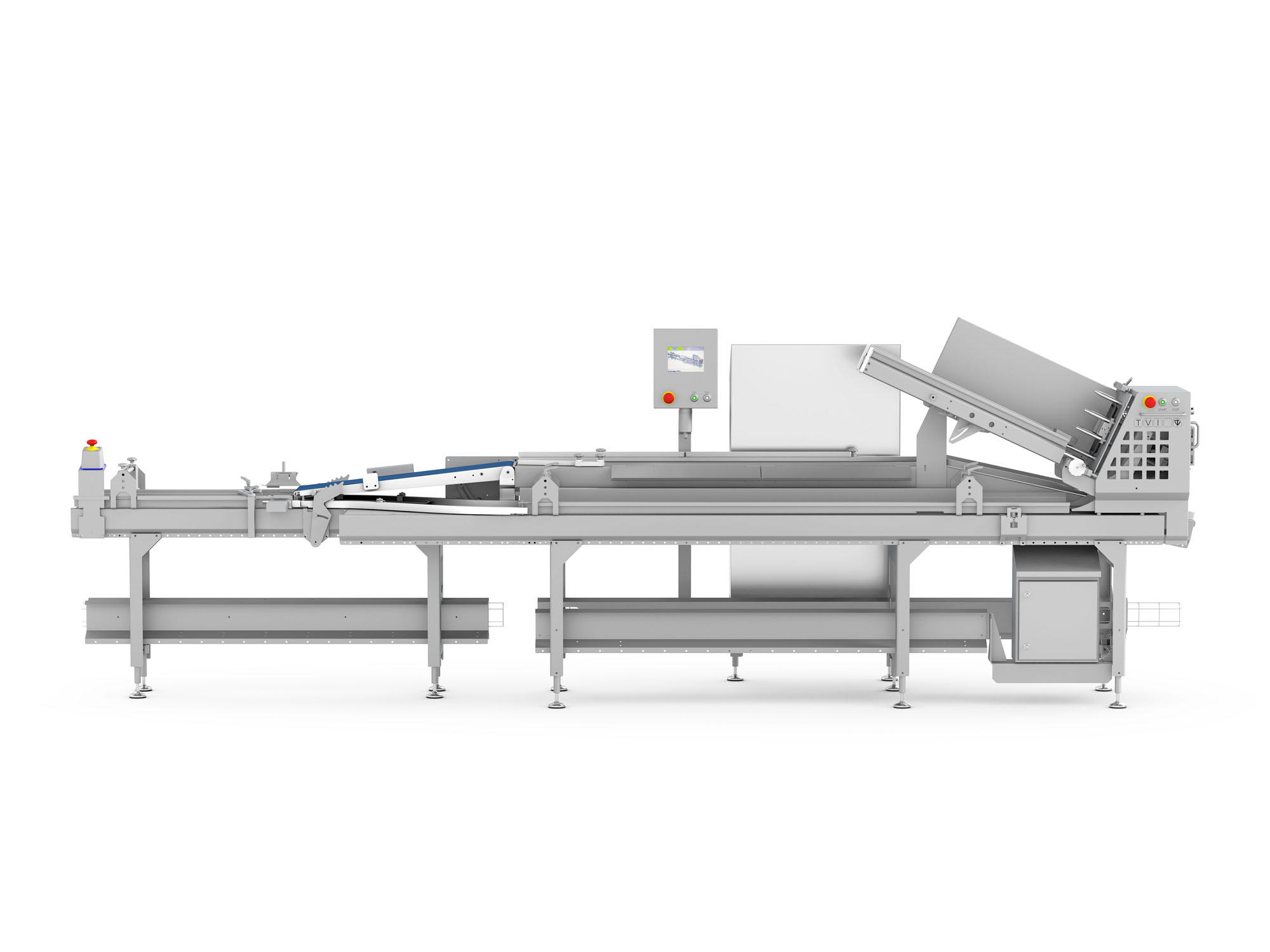

AIF 500 directload

Automatic tray filling with a knife-edge conveyor

- Can be combined with MIS 3000-4000 as a standalone unit (without GMI 500 for catch-weight portions only)

- Both manual and automatic tray filling are possible (depending on the product)

GMI 500 multitray

Weighing and sorting unit for fixed-weight portions consisting of:

- Dynamic scale

- Sorting with pushers

- Buffer belts for under- and overweight portions

- Tendency control with feedback for portioning machine